Your cart is empty

Reed Switches

PrintCutting, Bending, Mounting Instructions

During operation precautions should be taken to prevent from mechanical damage leading to glass leakage, damage of the sealing area and terminals.

Cutting and Bending of Reed Switch Terminals

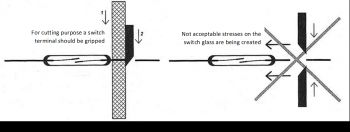

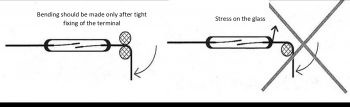

Cutting (Fig.1) and bending (Fig. 2) of terminals should be performed if only a reed switch and its terminals is protected from damage. To do it special tools should be used to avoid a mechanical stress on the sealing area.

Fig. 1- Correct and incorrect ways of cutting terminals. Tight fixing of the terminal is a must

Fig. 2 – Correct and incorrect ways of bending terminals. Tight fixing of the terminal is a must

When cutting and/or bending it is recommended to grip a part of the terminal close to a glass to metal seal area but not to glass itself. It is necessary to bear in mind that cutting and bending of terminals leads to OAT and RAT change (increase).

Re-bending is not permitted.

Mounting instructions

Mounting of reed switches should not lead to the damage of glass seal with terminals.

An adequate spacing between reed switches should be provided.

To connect a reed switch to the circuit flexible wires with the section not exceeding the switch terminal section should be used.

While operating and testing reed switches installed into an equipment precautions should be taken preventing from carrying currents across them and voltages exceeding maximum values acceptable for each switch part number.

When disassembling precautions should be taken to avoid glass and seal leakage.

Soldering, Welding of Reed Switches

Reed switch terminals subject to an electrical connection by soldering shelf solderability within 12 months after production date with no additional measures taken.

A reed switch is resistant to soldering heat as per IEC 68-2-20, test Тв, method 1A: temperature in the solder bath (260±5) °С, exposure time (5±1) s.

Solderability test is in compliance with IEC 68-2-20, test Та, method 1: temperature in the solder bath (235±5) °С, exposure time (2,0±0,5) s; accelerated aging 3: 16 hrs at 155 °С dry heat (test Ва).

It is acceptable to use reed switches both for through-hole and SMD processes,

For through-hole mounting soldering is being performed by soldering iron or wave solder.

Touching glass by a hot soldering iron and an accidental deposition of hot solder drops on the glass is not acceptable.

A recommended temperature of the soldering iron tip is 260°С max., soldering time 3s max.

During re-soldering time is needed to let switch terminals be cooled down after previous heating.

A recommended temperature for wave soldering is 270 °С max. for 10 s.

It is possible to use reed switches for SMD technology. A solder paste is applied by a screen printing process, reed switches with formed terminals are PCB mounted and paste is reflow soldered in the oven. A recommended temperature for reflow soldering is 260 °С max. for 20 s, 217 °С for 90 s.

For a reed switch welding is more critical than soldering since welding temperature is much higher. A heat zone is spreading up to one end of the glass seal, meanwhile a temperature at the other end of the seal is much lower. A high temperature change can lead to seal damage and as a result to no function of the reed switch.

During soldering and welding heat screens and sinks should be used to remove hazardous overheat.

Optimum welding conditions should be tested for each case.

An ultrasound should not be applied for reed switch cleaning and soldering. An effect of ultrasound waves of 10-250 kHz can lead to a change of the switch OAT and RAT or cause glass damage.