Your cart is empty

Reed Switches

PrintMOUNTING INSTRUCTIONS

Reed switches can be used both in plug-in and PCB mounting.

When mounting extreme caution should be exercised not to exert any undue stress that can result in damage or leakage of the reed switch. It is recommended to provide an adequate spacing between the reed switches.

When it is necessary to connect more than one wire to the leads the second and all next wires must be soldered (or welded) to the earlier soldered wire but not to the lead. The wire section must be equal to the reed lead section.

When welding or soldering reed switches deformation should be minimal. The output power of the solderer must not exceed 100 W. The time of continuous heating of the leads should not exceed 3 sec.

In case of re-soldering time is needed for the switch to be cooled after the earlier heating. Soldering is permitted at a temperature of the soldering iron of not more than 2600C.

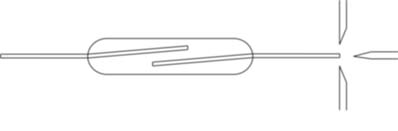

Recommended distance between the glass end and a bending point should be 3mm min. When bending a reed switch but not glass body should be firmly hold to avoid a broken glass. Re-bending is not acceptable. Figure 1 shows cutting techniques.

Figure 1

Note: bending and cutting can change pull-in and drop-out characteristics.